Drywashing: Best Practices for Getting the Most Gold

By Chris Ralph

Here I am doing some drywashing in Nevada, targeting very fine gold. Despite the effort, the recovery rate in this location fell short of my expectations.

Drywashers can be amazingly handy and I've gotten a lot of gold with mine. While wet processing is nearly always faster and more efficient at getting the gold out of gravels, there are times when a prospector needs to be able to process dry materials. It's just a fact that some goldfields are located in dry, desert environments and water is hard to come by in those places.

Drywashing is very popular in the desert regions, and you will see the Arizona or New Mexico folks and sometimes prospectors who work the deserts of Southern California doing a lot of drywashing, but elsewhere it's not nearly as popular.

My father feeding a drywasher in the Sierra gold country. The dry summer conditions in this region present good opportunities for recovering gold through drywashing.

I grew up in Southern California and did a lot of desert prospecting back when I lived there, and when I moved north, I took my drywasher and knowledge of desert prospecting with me. It didn't take long for me to notice how dry some spots in the Sierra Nevada gold country were during the summer dry season. I tried drywashing some gravel that had no water close by, and it was no surprise that the method was just as successful as it was in the desert. That's how I ended up drywashing in the mother lode - in places where very few prospectors in this region consider the possibilities of drywashing. The ground in the Sierra is pretty dry during the summer, so it works for drywashing. I think a lot of prospectors miss the potential of forested locations because drywashers are thought of as equipment only for desert locations. The truth is, they can work well in any location where the gravel is dry and water for sluicing is not close at hand.

The drywasher is basically designed to be a short, waterless sluice, where a flow of air coming up through a porous cloth medium on the underside of the drywasher sluice box takes the place of flowing water. The vibrations and flow of air replace the function of water in the normal sluice, allowing the gold to settle downward and be caught. The bottom of the recovery box consists of a thin, light weave fabric cloth. Beneath the riffle box is a bellows or other source of blowing air, and the air moves upward through the cloth. The force of this air lifts the gravel and allows it to move through the recovery box almost like a fluid. The combined shaking and classifying action of the drywasher allows the gold particles to settle to the bottom where they are captured by the riffles.

Drywashers are operated by shoveling gold-bearing gravels onto an upper box that is covered with a screen. The larger rocks that are too big for the screen slide off. The gravels that are small enough to go through the screen are then fed down into the lower recovery riffle box, which is inclined with cross riffles much like a sluice. They normally are small enough to be moved around by a lone prospector, comparatively inexpensive, and easy to use. In some places they work well getting nearly all the gold, while in others there are problems because a large percentage of the very fine gold can be lost.

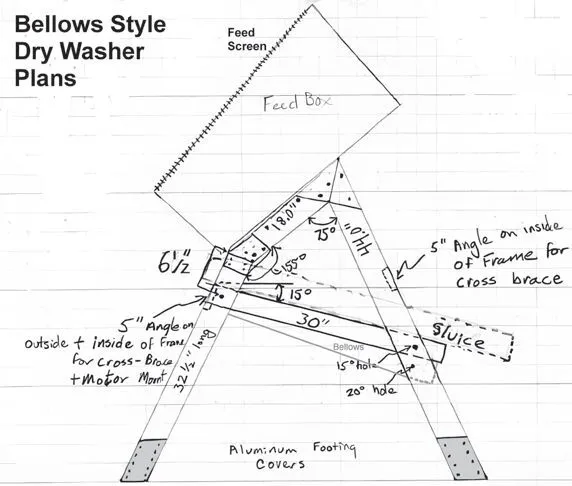

There are two main varieties of dry washer. The first is a bellows-type, which puffs air as the bellows are operated. The other design employs a motorized blower to provide a continuous flow of air. Both the bellows and blower-type designs are still used on modern drywashers, and while some prospectors have their preferences, both are reasonably efficient at catching gold.

The original inventor of the drywasher is unknown, but it was probably invented by a Spanish or Mexican prospector working on North American dry placers sometime in the early to mid-1800s. The idea was a big improvement on previous methods, and the design spread fast, so that by the second half of the 1800s, these machines were in common use in many of the desert goldfields of both North America and Australia. In the early days, the bellows type was generally more popular. In recent years, both designs are widely used by individual artisanal miners in Mongolia, Mexico, Africa, Australia and other dry, desert locations around the world.

One of the most frequent questions I get asked is what percentage of gold will a drywasher recover. The unfortunate answer is that it all depends - because the results are all over the map. I have run two tests on this. One was with what I think were pretty much the best possible conditions with coarse gold and minimal clay. Some of the gold was coarse enough to find with a metal detector. For that test, I got 97% of the gold drywashing compared to what I got sluicing. That is an excellent rate for dry processing. I was very happy with it, given the fact that the drywasher does not recover gold quite as well as a wet process like a sluice. However, in the spring of 2024, I did another test. This time I did my testing with pretty much the worst of conditions. The gold at this other location was all very fine, mostly less than 30 mesh. There was plenty of clay. I got 35% recovery - and that is awful. So, the answer to how well does a drywasher work depends a lot on how coarse the gold is. If a lot it is about 12 mesh or better, you should get good results. If it's all below 30 mesh, you likely won't do very well. Clay also causes problems - the more clay that is present, the worse your results will be.

Ten Best Practices for Drywashing Success

A historical glimpse of drywashing at Coolgardie, north of Barstow, California, over a century ago. Drywashing has been a key method for gold recovery in desert regions for generations.

1. Set it up as close to the dig hole as possible, but leave room for tailings.

Take time and think about where you will set up your drywasher. If you can set it up right at your dig spot so you can shovel directly into the drywasher, that is the best and most efficient location. If you do have to bucket up your gravel and carry it to the drywasher, try to get it as close to the dig hole as possible so you can minimize the distance you are carrying the buckets. Remember that drywashers are portable, so move your drywasher around as necessary to follow the golden paystreak.

2. Only process fully dry material.

To get good recovery, the drywasher requires that the sand and gravels being processed be fully dry. If the gravels are damp, the drywasher will not work properly and will lose gold. Because of this, just a bit of rain can really ruin the ground in an area for several days and sometimes more. Even slightly damp dirt is a problem. If you can grab a handful and squeeze it together and the stuff stays as a clump in your hand, it is too wet. One alternative is that when the ground you want to run is a bit damp, it is common to spread it out on a tarp for an hour or two to let it dry in the sun before processing.

3. Thoroughly break up all dirt clods.

This single clod of dirt contained nearly a quarter-ounce of gold! While this is an extreme example, it illustrates the importance of breaking up dirt clods when drywashing. Clods like this can roll right off the screen.

The biggest problem with losing gold with a drywasher happens when there are pieces of gold that get caught up in dirt clods. Now, you can lose gold in dirt clods in a sluice box too if the clod does not break up and dissolve before it rolls out the back of the sluice. The same happens with a drywasher when the clod of dirt holds together. It will work its way on down through the dry sluice recovery area and out into the tailings.

Because of this, any clods and clumps of dirt must be broken up before they are run through the drywasher. The best material for drywashing (to get the highest gold recovery) should be fully dry and sandy with a minimum of clay. Clay will bind the smaller gold to rocks and pebbles, such that they will pass through the drywasher, and that gold will not be recovered. If you have really heavy clay materials, they must be carefully broken up by hand before they go into the drywasher. While you are running the gravels, if you see any clods on the screen as you are feeding the material in, be sure to bust those up as you see them.

4. Don’t dust yourself out.

Drywashing in a desert placer district in Nevada. The nearest water for processing is many miles away from here, so drywashing is the only option.

Drywashing, by its very nature, is a dusty process because you are blowing air through loose, dry dirt. However, the amount of dust from drywashing can vary hugely; it just depends on how much clay and other very fine material is present in your gravel. I have seen situations where the dust cloud was almost as big as a house. I have also seen situations where there was only a little bit of dust. Most cases are somewhere in between.

When setting up your equipment, it is smart to plan out your operations so that you can stay up wind as much as possible and minimize the dust you breathe. Sometimes it's worthwhile to even consider wearing a dust mask, especially when the dust cannot be avoided. Over the longer term, breathing large quantities of dust particles can potentially do serious damage to the tissues of your lungs, since drywashing frequently produces copious amounts of dust. So, it's important to be careful to avoid the dust. There are even some viruses or other disease-causing agents that can be hiding in the soil. Valley fever is perhaps the best known of these, but there are others as well, and some are quite serious. Overall, it's good to take all reasonable precautions to avoid the dust.

5. Feed gravels evenly and on the level (side to side).

Here I’m breaking up dirt clods to release the gold trapped inside. This area had a fair amount of clay and much of the material I dug was in the form of clay.

When setting up your drywasher, make sure the flow across the recovery box is even and that it is not tilted to one side or the other. An even flow across the entire dry sluice box section will give you the best recovery of gold. This should also be checked from time to time as you are operating the drywasher. It's easy to bump the unit as you are feeding material in and get it off kilter. So, keep an eye on how it is operating while you are processing the gravels.

Most drywashers have an adjustment to control the flow rate coming from the upper screen box into the lower recovery box section. Be sure to adjust the flow so you are not overloading the riffles in the recovery box. Swamping the box with too heavy a flow will bury the riffles and lead to lost gold. This is another aspect to keep an eye on while you are processing the gravels.

6. Clean up the recovery box regularly.

This is about a quarter ounce of gold I recovered using a drywasher in the pines of the Sierra Nevada gold country. The gold coin is just for scale - it wasn’t something I found.

Unlike the typical wet sluice box, where you could go a full day between cleanups, the drywasher is different. A regular cleanup of the drywasher sluice box must be done to prevent excessive loss of gold. Perhaps two hours is the very most you would want to run between cleanups, much better would be 90 minutes of operation - this equates to about one cubic yard of material processed per cleanup. During cleanup, the riffle box is lifted out and turned over and shaken into a large bucket or tub. Gentle tapping of the riffles gets all the material out and into the bucket. For most drywashers, cleanup is quick, so it's not a problem.

Before dumping the concentrates, you can also check the riffles for any visible nuggets at this time. Usually, the coarse and some fine gold are visible at this time if you are doing well. The gold will be most abundant in the upper riffle section. The lower riffles may contain a few colors, but the majority of all the recovered gold is caught in the upper two riffles. It's possible even if there is no visible gold, you still may be doing OK, but if nothing is visible, it might be time to do some sample panning to test how much gold is in your gravels.

The concentrates from the drywasher are normally further processed by panning, as with any placer concentrates, and the gold removed. If water is very scarce, and you don't want to carry in that amount of water, the concentrates may be saved and processed later at another location with more water. The concentrates will weigh only a tiny fraction of the gravel material treated. I normally bring along sufficient water or take my concentrates to a water source (often at the spot where I am camped). Testing is important because you need to see if you are following the pay-streak.

7. Sample repeatedly to find a good spot.

The most important thing in achieving drywashing success is to process gold-rich gravel! Far too many prospectors just find a likely spot and dig in - and even when the results are not that good, they stay in the same spot. It is super important to sample around to find the best spot for your drywasher. All placers are spotty in nature and there might be a spot 20 times richer than the one you are working just 50 feet away. However, if you do not sample and test to find those rich spots, you will never know. Test and test again until you find a better spot. The time spent sampling and testing will be well worth it.

I use my metal detector as the main sampling tool for my drywasher. When I find a spot with my detector that has a number of nuggets concentrated in a small area, I know there is a fair chance that there might also be some smaller fine gold associated with it. To get that smaller gold, I want to dig the area up and process the gravel with my drywasher. The drywasher is just the right equipment to pick up that fine gold. The truth is that sometimes there is actually more fine gold present in a paystreak than the gold contained in the coarse nuggets that are large enough to see with a metal detector. There is a bonus because the drywasher digging exposes more bedrock for metal detecting - this is a byproduct of digging out the gravels for drywashing.

The real goal of digging out and drywashing the paystreaks you find with your detector is getting all the gold - both the gold your detector can find, and the gold that is too small or too deep to see. So, if you find a nice nugget patch, don't forget about the fine gold in your patch, test it and find out what you really have. Those nugget patches are not easy to find, so be sure to drywash it and don't leave a significant portion of the gold you have found behind.

8. Don’t run the drywasher when no material is feeding into it.

The original Thompson Drywasher. Photo courtesy of Peggy S.

Normal drywashing efforts consist of digging for a while, then running the drywasher to process the material you have dug. Then, you repeat the process by digging more material and processing that. What you don't want to do is to run material and leave the drywasher running while you go and dig more. This is because the gold can work its way through the drywasher and out into the tailings if the unit is run with no feed for an extended period of time. With my 12V electric motor drywasher it is just a matter of flipping a switch, but gas-powered units can be more of a pain to start and stop. Always be sure to stop the drywasher operations when you are not feeding material into it.

9. Clean up the bedrock carefully.

Gold I collected from a nugget patch initially found metal detecting. The coarser gold on the right was detected, and I later drywashed the remaining gravel to recover the finer gold on the left. The dry-washed gold actually weighs more than the detected gold.

In dry areas it's easy to leave the bedrock where it's not quite clean enough. Many guys who do drywashing regularly also use a dry vac unit along with their drywasher. The dry vac does a great job of cleaning out crevices in bedrock so that you can capture the gold that has been hidden in the bedrock. Another method is to carefully whisk broom the bedrock surface, but it is hard to broom these types of places up, and the vac does a much better job. The material captured in the vac bucket is then fed into the drywasher.

10. Use a metal detector to check your dig hole and tailings pile.

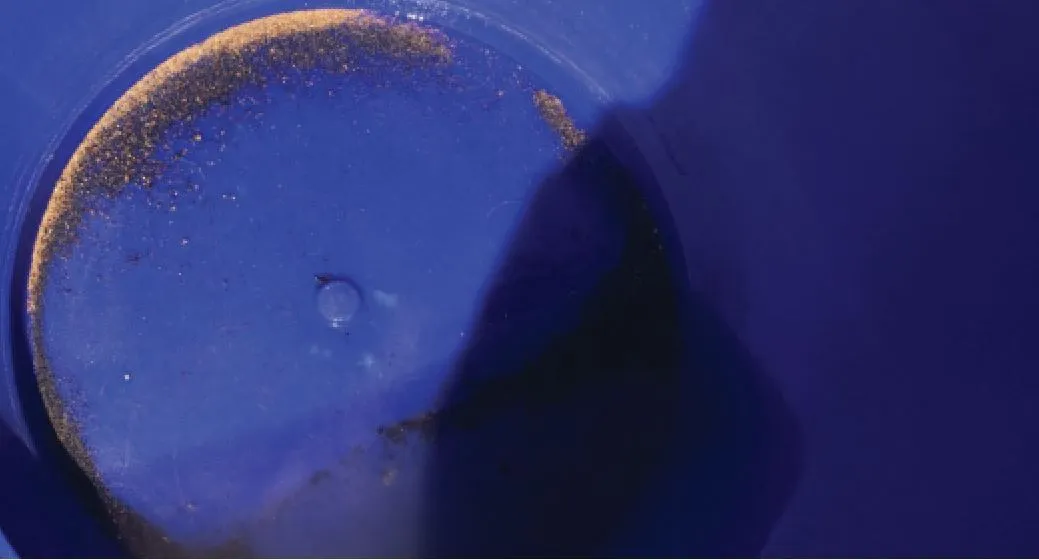

If the gold in your area is as fine as this, drywashing probably won’t perform well. With material like this, I achieved only a 35% recovery rate.

When you dig a hole to process the gravels in your drywasher, always carefully check the bedrock you expose with your metal detector, because nuggets can hide down in fractures and crevices that are not easily visible. In testing the bedrock with a metal detector, I've found I've accidentally left some nice gold on bedrock I truly thought was clean. Your metal detector can see that hidden gold and tell you if there is gold present that you have missed. In the same way, the walls of your dig hole should always be checked with a metal detector. I once found a half-ounce nugget that was out about 8 inches in front of where I was going to stop digging. The detector told me I needed to keep going and not to quit.

Chris Ralph has a degree in mining engineering from the Mackay School of Mines in Reno. He has worked for precious metal mining companies conducting both surface and underground operations. After working in the mining industry, he has continued his interest in mining as an individual prospector. He has a YouTube channel at Chris Ralph, Professional Prospector with many educational videos. He can also be reached at P.O. Box 3104, Reno, Nevada 89505; or via email at chrisralph218@gmail.com

0 comments